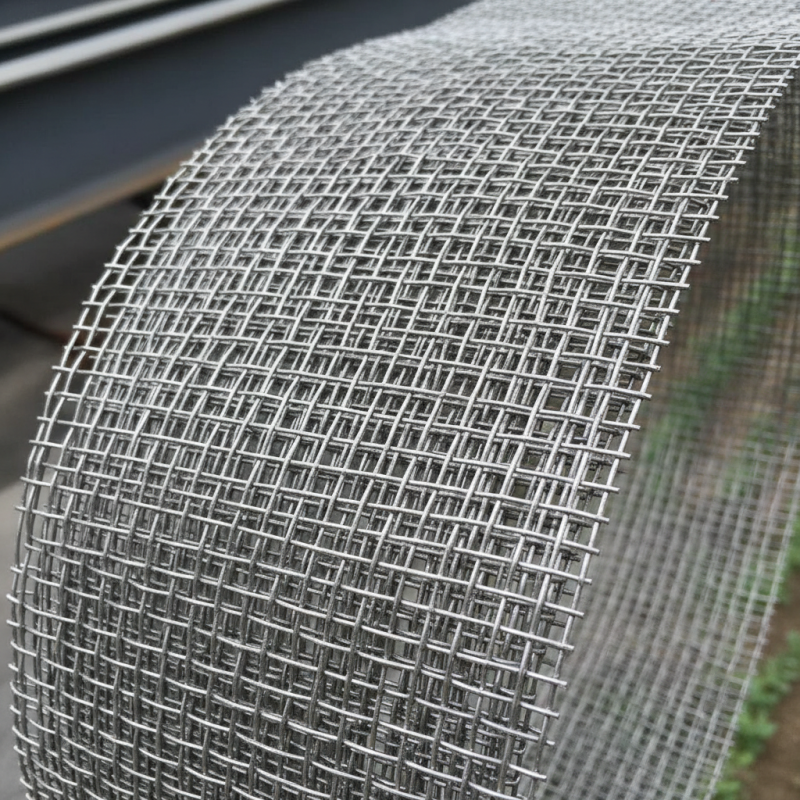

Choosing the right stainless steel woven wire mesh can be a daunting task. This material is versatile and durable, making it popular in various industries. From construction to agriculture, its applications are vast. However, not all stainless steel woven wire mesh is created equal.

It’s crucial to consider factors such as wire diameter, mesh size, and material quality. Selecting the wrong specifications can lead to inefficiencies. Poor-quality mesh may wear out quickly, resulting in costly replacements. Reflecting on your needs is essential. Understand how the mesh will be used and its environment.

In the following sections, we will explore key tips for making an informed choice. Remember, the right mesh can improve your project’s overall efficiency and longevity. Making a thoughtful decision is vital, as mistakes can be expensive.

When selecting stainless steel woven wire mesh, various factors come into play. Consider the material's durability. Woven wire mesh should withstand harsh conditions. Check the grade of stainless steel used in construction. Different grades offer varied resistance to corrosion. A lower grade might not last long in outdoor settings.

Another important aspect is the mesh size. The size affects both strength and application. A finer mesh can filter smaller particles, but it may also reduce airflow. Think about your project needs. Do you require strength, or is filtration the priority? Balancing these needs can be challenging.

Lastly, consider the wire diameter. Thicker wires provide more strength but might be less flexible. A thinner wire is often cost-effective but could be prone to damage. Evaluate how each aspect fits into your specific project requirements. It’s all about finding the right compromise. Take time to reflect on possible applications and limitations before making a final decision.

When selecting stainless steel woven wire mesh, understanding the stainless steel grades is crucial. Different grades offer specific properties that cater to diverse applications. For instance, 304 stainless steel is commonly used due to its excellent corrosion resistance and versatility. It's a popular choice in food processing and construction.

On the other hand, 316 stainless steel provides superior corrosion resistance, particularly in marine environments. This grade contains molybdenum, enhancing its durability against salt and chlorine. However, it may be more expensive. Weighing the cost versus benefits can be challenging. Sometimes, lower grades can suffice for less demanding environments.

It's essential to consider the wire mesh's intended use. Will it be exposed to harsh chemicals or high temperatures? These factors play a significant role in your choice of grade. Mistakes in selecting the appropriate grade can lead to premature mesh failure. Thus, evaluating your specific needs against available grades might require some trial and error.

| Grade | Corrosion Resistance | Strength | Temperature Resistance | Common Applications |

|---|---|---|---|---|

| 304 | Good | Moderate | -196°C to 800°C | Food processing, kitchen equipment |

| 316 | Excellent | High | -196°C to 870°C | Marine, chemical processing |

| 430 | Fair | Moderate | -50°C to 800°C | Cutlery, automotive trim |

| 2205 | Excellent | Very High | -50°C to 300°C | Oil and gas, structural applications |

When selecting stainless steel woven wire mesh, considering mesh aperture size is crucial. The aperture size affects both filtration performance and the material's strength. A smaller aperture captures fine particles effectively. However, it may reduce airflow and fluid flow rates. This balance can be challenging to achieve.

Aperture size also dictates the mesh’s strength. Larger apertures might compromise structural integrity under stress. Small sizes offer more strength but can limit versatility. It's essential to evaluate your specific needs. Will the mesh handle high pressure? Or is filtration the primary goal?

Tips to keep in mind:

- Assess the application thoroughly.

- Experiment with various sizes to find the best fit.

- Reflect on the potential trade-offs.

Understanding the impact of aperture size can make all the difference in performance and durability.

When considering stainless steel woven wire mesh, durability is paramount. This type of mesh is designed to withstand harsh environments. It resists wear from abrasion and impact, ensuring a long life. For instance, in outdoor applications, the mesh holds up against extreme weather. However, it’s crucial to assess the grade of stainless steel. Not all grades offer the same level of durability.

Corrosion resistance is another vital feature. Stainless steel mesh can resist rust in moist environments. This property makes it ideal for marine applications or industries that deal with water. Nonetheless, some factors can affect corrosion resistance. The presence of chlorides can initiate pitting. Therefore, one must consider the specific environmental factors before making a choice. Regular inspections can help identify any signs of wear or corrosion. These steps ensure that the mesh remains effective.

Stainless steel woven wire mesh finds applications in various industries due to its unique properties. Its durability and resistance to corrosion make it ideal for harsh environments. In the food industry, this mesh is often used for sieving and filtering. It ensures hygiene and safety, meeting strict health regulations.

In the construction sector, stainless steel woven wire mesh reinforces concrete structures. This adds strength while maintaining flexibility. However, choosing the right type can be tricky. Not every mesh suits every application. The size of the openings and mesh thickness varies widely. This can impact performance and longevity.

The mining industry also utilizes this material for separation processes. Here, it separates valuable minerals from unwanted materials. Yet, improper selection could lead to inefficiencies. It’s crucial to evaluate specific needs before making decisions. A mismatched mesh type can result in operational setbacks. Users must consider the mesh's tensile strength and wire diameter carefully.