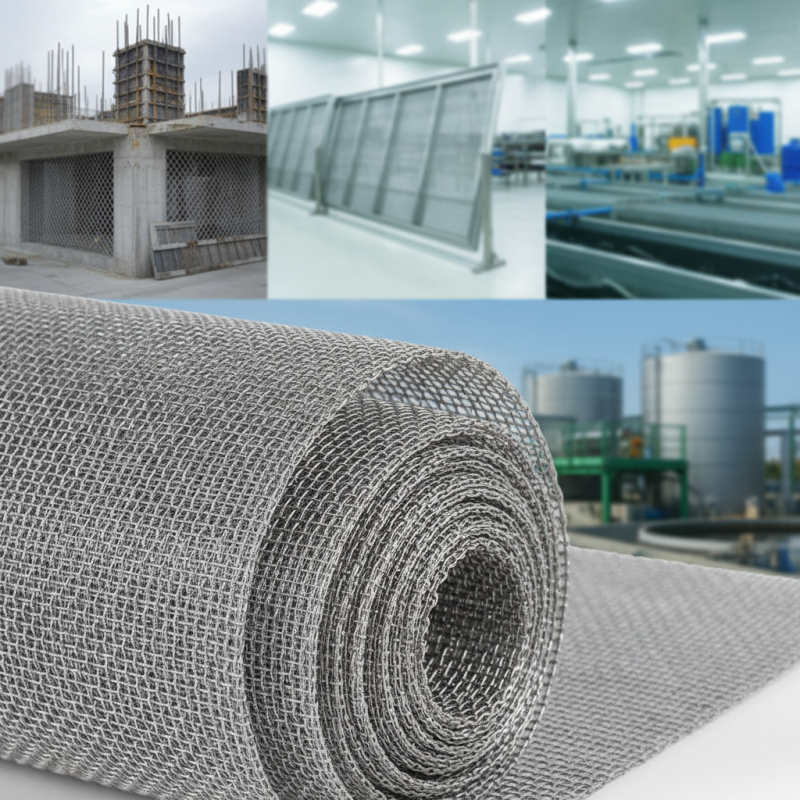

stainless steel wire mesh is a versatile material used in various industries. The global market for stainless steel wire mesh is projected to reach 1.2 billion USD by 2026. This growth stems from its durability and resistance to corrosion. Industries such as construction, food processing, and filtration heavily rely on stainless steel wire mesh for its strength and reliability.

In construction, stainless steel wire mesh provides essential support in concrete structures. It enhances strength and reduces cracks. In the food industry, its hygienic properties make it an ideal choice for screens and filters. Many factories use it to ensure food safety and quality. Its application in filtration systems is noteworthy, particularly for water treatment and chemical processing.

While stainless steel wire mesh offers many advantages, it is essential to consider its cost. Sometimes, cheaper materials might be available. Buyers must weigh longevity against immediate expenses. Choosing the right type involves understanding specific needs. Not all applications require the same mesh type or size. It's a decision that warrants careful thought.

Stainless steel wire mesh is a versatile material. It consists of woven strands of stainless steel. This composition provides durability and resistance to corrosion. The mesh can vary in thickness and weave pattern, influencing its strength and application. Common grades used include 304 and 316 stainless steel, known for their balance of cost and performance.

The uses of stainless steel wire mesh are extensive. It is ideal for filtration in industrial applications. The mesh can separate solids from liquids effectively. In construction, it aids in reinforcing concrete structures. It is also popular for creating decorative elements in architecture. Some people use it for craft projects and DIY home improvements. However, the manufacturing process can vary, and quality may not always meet expectations. This inconsistency should prompt caution when choosing material for essential applications.

Stainless steel wire mesh comes in various types, each offering unique characteristics. Common types include welded mesh, woven mesh, and perforated mesh. Welded mesh is created by welding stainless steel wires together. This type is strong and durable, suitable for heavy-duty applications like fencing or reinforcement. Woven mesh, on the other hand, is made by intertwining wires. It is more flexible and often used in filtration and screens.

Understanding the specific characteristics can help you choose the right type. For example, woven mesh may allow better airflow but might not support heavy loads. Consider where the mesh will be used. If moisture exposure is likely, opt for corrosion-resistant alloys.

Tips: Always test a small sample before full installation. This can help identify any shortcomings in the selected mesh type. Evaluate the mesh in real-world conditions, noting any potential issues. Don’t hesitate to seek expert advice to avoid costly mistakes.

Stainless steel wire mesh is a versatile material used across various industries. Its properties include corrosion resistance, durability, and strength. As a result, it finds applications in construction, food processing, and filtration systems.

In construction, stainless steel wire mesh is often used for safety barriers and reinforcement in concrete structures. According to a report by MarketsandMarkets, the global wire mesh market was valued at over $4 billion in 2022, with significant growth expected. In the food industry, it serves as filters and screens, ensuring the hygiene of processed products. The mesh allows for airflow while preventing contamination.

Tips: When selecting wire mesh, consider the required gauge and expertise. Thinner mesh may be less durable but offers flexibility. Research specific regulatory requirements for food applications. Remember, mesh that is too coarse can allow unwanted particles through.

In filtration systems, stainless steel wire mesh is crucial. It separates solids from liquids effectively. However, not all applications require high-grade mesh. Evaluate your project needs carefully. Sometimes, a different material may suffice, and stainless steel can be overkill. While it offers excellent performance, costs should be weighed against necessities.

Stainless steel wire mesh is valued for its durability and resistance to corrosion. Its use spans various industries, including construction, filtration, and agriculture. According to industry reports, the global market for stainless steel wire mesh is expected to grow at a compound annual growth rate (CAGR) of 5.3% from 2021 to 2026. This growing demand highlights its significant advantages.

One major advantage of stainless steel wire mesh is its strength. It can withstand harsh environments and heavy loads. This makes it ideal for filtration applications, where maintaining structural integrity is crucial. In agriculture, it serves as a protective barrier for crops and livestock, ensuring longevity.

Another benefit is its versatility. Different wire gauges and weave patterns provide a wide range of applications. However, not all stainless steel mesh is created equal. Some may lack the proper finish, impacting its utility. Proper selection is essential to achieve the desired performance. Reports show that about 15% of users face issues due to incorrect usage. This highlights the need for careful consideration in the selection process.

When it comes to maintaining stainless steel wire mesh, regular cleaning is crucial. Use mild soap and warm water. A non-abrasive cloth can prevent scratches. For tough stains, a mix of vinegar and water works wonders. Remember to rinse thoroughly after cleaning. This simple routine keeps the mesh looking new.

Corrosion is a concern, even for stainless steel. Pay attention to the environment where the mesh is placed. Moisture and salty air can lead to rust. Consider applying a protective coating to enhance durability. Inspect the mesh regularly for early signs of deterioration.

Stainless steel wire mesh can be useful in various applications, but improper care can shorten its lifespan. It is essential to approach maintenance with intention. Observe any changes in appearance or structure. Each check can reveal potential issues before they become serious problems. Be proactive and keep your mesh in optimal condition.

| Use | Material Type | Wire Diameter (mm) | Mesh Size (mm) | Common Applications |

|---|---|---|---|---|

| Screening | 304 Stainless Steel | 0.5 | 1.5 | Construction, Mining |

| Filtration | 316 Stainless Steel | 0.3 | 2.0 | Water Treatment, Food Industry |

| Caging | 304 Stainless Steel | 0.8 | 3.0 | Agricultural, Animal Housing |

| Architectural | Austenitic Stainless Steel | 0.7 | 4.0 | Building Facades, Interiors |

| Security | 304 Stainless Steel | 1.0 | 5.0 | Fencing, Grilles |