In the pursuit of sustainable industrial growth, optimizing Power Energy efficiency has emerged as a critical necessity. According to a report by McKinsey & Company, industries account for over 30% of global energy consumption, and this figure is projected to rise significantly in the coming decade. Furthermore, the International Energy Agency (IEA) emphasizes that enhancing energy efficiency within these sectors could lead to a potential reduction in energy use by 20% by 2040, translating into substantial cost savings and lower greenhouse gas emissions. As industries increasingly face pressure to balance economic growth with environmental responsibility, understanding the strategies for improving Power Energy efficiency becomes vital. This blog delves into the transformative practices and technologies that can help industries not only meet regulatory standards but also drive profitability through sustainable energy management.

In today's industrial landscape, reducing energy wastage stands out as a critical strategy for fostering sustainable growth. The push for energy efficiency not only benefits the environment but also translates into significant cost savings for companies. By adopting innovations in advanced materials and implementing smart technologies, industries can optimize their operations, minimize excess energy consumption, and meet evolving regulatory requirements.

For example, integrating artificial intelligence into manufacturing processes enhances efficiency and adaptability, allowing businesses to increase precision while simultaneously reducing their energy footprint.

For example, integrating artificial intelligence into manufacturing processes enhances efficiency and adaptability, allowing businesses to increase precision while simultaneously reducing their energy footprint.

Embracing circularity is another vital aspect of minimizing energy wastage in industrial operations. By rethinking resource usage and focusing on recycling and reusing materials, industries can significantly cut down on waste and emissions. This approach not only aligns with sustainability goals but also creates economic value through reduced resource costs and enhanced productivity. As companies explore new methods for energy-efficient construction and manufacturing, they position themselves at the forefront of a sustainable industrial future, thereby contributing to a greener planet while securing their competitive edge.

The shift towards renewable energy sources in factories is not just an environmental necessity; it’s also a strategic advantage for sustainable industrial growth. Utilizing solar, wind, and biomass energy can significantly reduce operational costs. For instance, factories that incorporate solar panels can slash their electricity bills and protect themselves from fluctuating energy prices. This approach not only enhances profitability but also promotes a cleaner production process, aligning with global sustainability goals.

Tip: Assess your factory’s energy consumption patterns and identify which renewable energy source best suits your operational needs. Solar energy can be optimal for locations with ample sunlight, while wind energy may be beneficial in more open and windy areas.

Moreover, implementing renewable energy sources can enhance a factory’s image, appealing to eco-conscious consumers and investors. Companies that prioritize sustainability are often viewed more favorably, resulting in increased brand loyalty and market share.

Tip: Consider engaging your employees in sustainability initiatives. Encouraging them to contribute ideas for energy efficiency improvements fosters a culture of responsibility and innovation within the company, turning staff into advocates for renewable energy solutions.

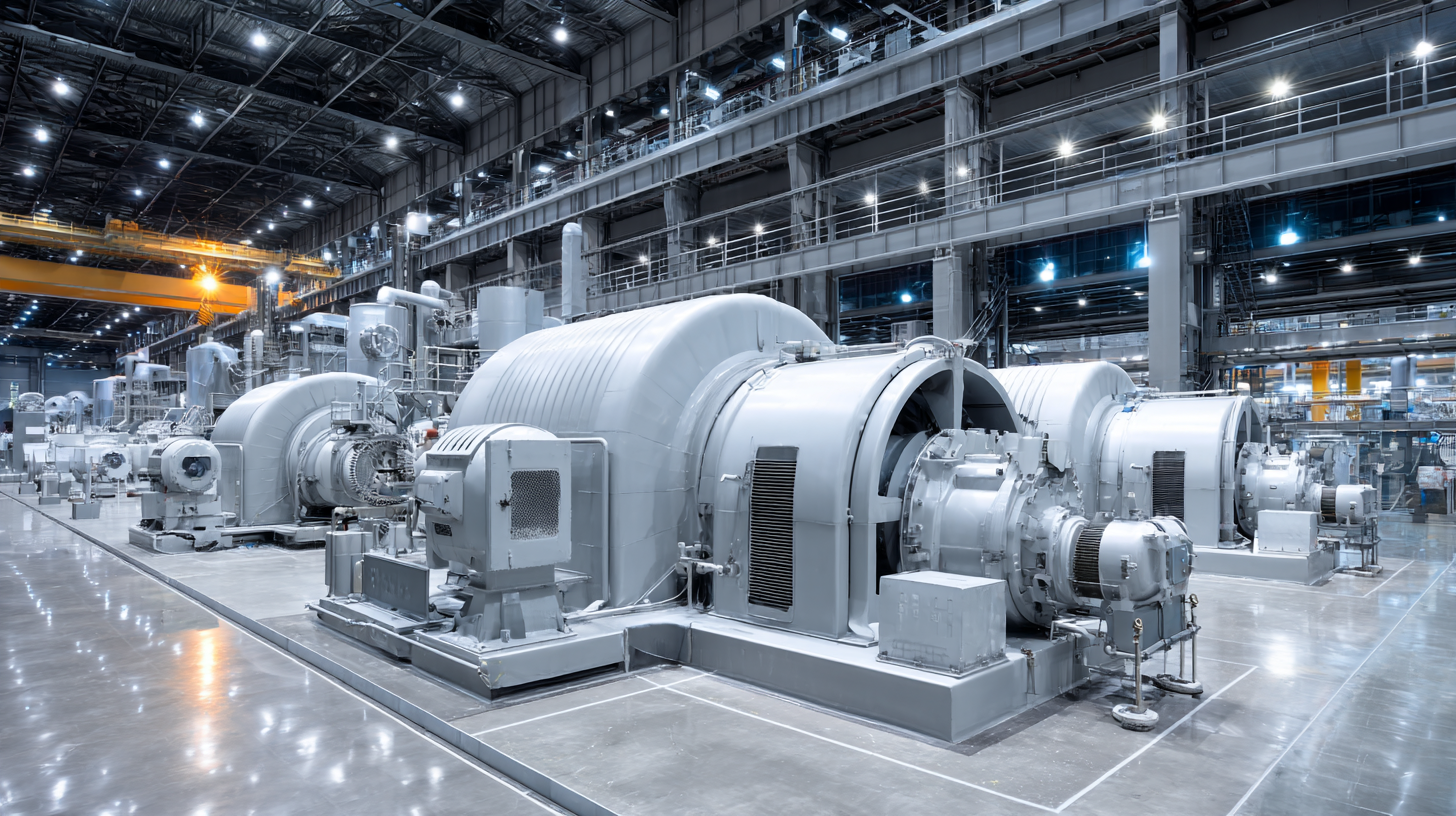

Energy efficiency is a crucial factor that directly affects operational costs and profit margins in the industrial sector. According to the International Energy Agency (IEA), improving energy efficiency can reduce energy consumption by up to 30%, significantly lowering operational expenses. For instance, a study by the American Council for an Energy-Efficient Economy (ACEEE) found that industries that implemented robust energy management practices saw an average increase of 15% in profit margins over three years. This illustrates how proactive measures in energy efficiency not only cut costs but also enhance overall financial performance.

To optimize energy efficiency, companies should consider implementing regular energy audits to identify inefficiencies in their systems. Simple upgrades, such as switching to LED lighting or more energy-efficient machinery, can yield substantial savings. Additionally, investing in advanced technologies like IOT-based monitoring systems can help track energy usage in real-time, allowing for timely interventions.

Another effective strategy is to engage employees in energy conservation initiatives. Creating awareness and encouraging staff to adopt energy-saving practices can foster a culture of sustainability within the organization. According to a study from McKinsey, companies that involve their workforce in energy efficiency programs can achieve up to a 10% further reduction in energy use, translating directly into improved profit margins.

Optimizing energy efficiency in industrial processes has become crucial for fostering environmental sustainability. Reports indicate that manufacturing is responsible for nearly 30% of global energy consumption, leading to significant carbon emissions. Implementing energy optimization strategies can lead to substantial reductions in this footprint, with studies showing that sustainable machining processes can enhance operational efficiency by up to 20%. By adopting a two-stage optimization approach that integrates environmental and economic objectives, companies can not only improve their manufacturing practices but also contribute to achieving national and global sustainability goals.

The role of artificial intelligence (AI) in enhancing energy efficiency is evident across various sectors. For example, AI-driven approaches have shown potential in reducing emissions in supply chain management, where sensitivity analysis can help optimize resource allocation, achieving up to a 15% increase in overall efficiency. Furthermore, when applied to bioenergy, AI can significantly improve waste management and energy conversion processes, showcasing how technology can be harnessed to align industrial growth with environmental sustainability. As industries continue to evolve, embracing innovation through improved energy optimization will be essential for ensuring a sustainable future.

Investing in energy efficiency is not merely a trend; it is a crucial strategy for industries seeking long-term benefits. According to the International Energy Agency (IEA), improving energy efficiency can lead to a reduction of up to 40% in energy consumption by 2040, significantly lowering operational costs and enhancing competitiveness. In an era where energy prices are volatile, industries that invest in energy-efficient technologies, such as high-efficiency motors and advanced lighting systems, can save millions annually, thereby redirecting funds towards innovation and growth.

Moreover, the U.S. Department of Energy estimates that every dollar spent on energy efficiency can yield a return of about $2.24 over time. This investment not only curtails greenhouse gas emissions but also positively impacts the bottom line; companies that adopt energy-efficient practices often experience a marked improvement in their sustainability ratings. Notably, the manufacturing sector, which accounts for nearly one-third of global energy consumption, stands to gain immensely from efficiency upgrades. By prioritizing energy investments, industries can enhance their productivity while contributing to a more sustainable environment, ultimately ensuring a resilient and prosperous future.